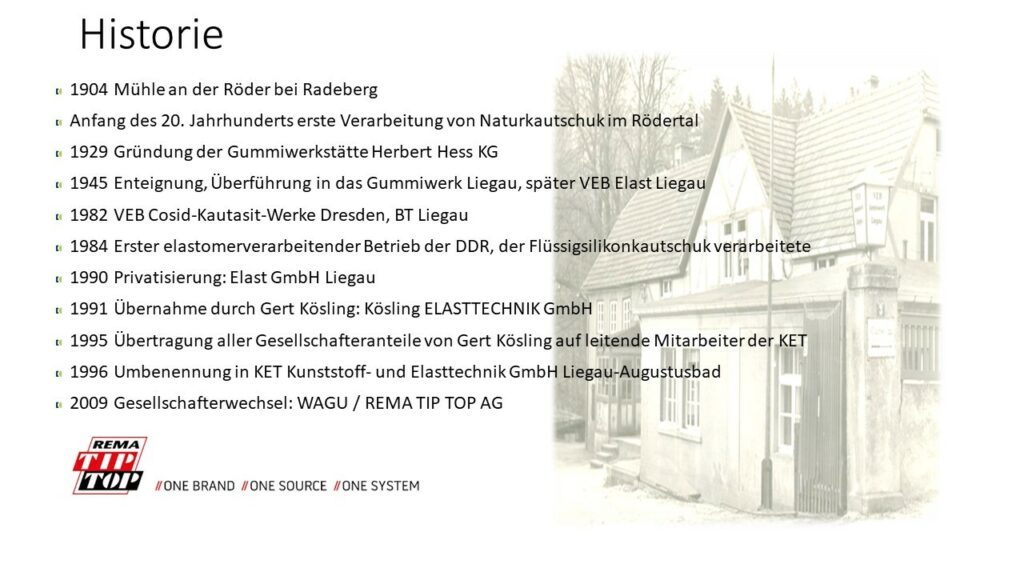

Looking back on more than a century of company history

KET Kunststoff- und Elasttechnik GmbH can look back on more than eleven decades of tradition in the processing of rubber, silicone and later also traditional plastic. During these years we have been able to continuously expand our experience and successfully master new requirements. Here you will find the most important stages in our company’s history.